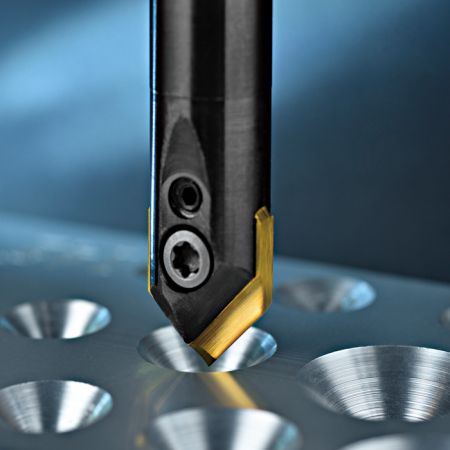

Indexable Center Series

Using the high-precision center drill and spot drill to achieve better drill and tap tool life is definitely the best choice to save costs and machining time:

Time-saving: When machining with a drill or tap, the tool can easily break if it is not accurately positioned, and it would take lots of time to remove the broken drill and tap. By using a precise center /spot drill can solve this problem immediately.

Cost-saving: The accurate center positioning center drill and spot drill improve the tool life of the drill and tap significantly by giving a precise center spot, it reduces the amount of tool used.

The YIH TROUN full series of indexable spot drills and center drills use fully ground carbide insert, which need to be replaced only when worn out but without the needs to replace the shanks. There are also a variety of long and short shanks that are interchangeable. The inserts are made of different grades in different angles and sizes:

Spot Drill: 90° / 90 + 142° / 142°

Center Drill: 60° / 60 + 120° / 90°

Spot Drill

Also known as positioning drills, a dedicated spot drill to milling machines. The two cutting edges are designed on balanced positions to decrease the high feed rotating runout and secure ultimate positioning precision.YIH TROUN Spot Drill features sandwich plug-and-clamp construction as well as special design with tapered key. It stays eccentricity ± 0.008mm, approaches almost zero eccentric in stationary status.YIH TROUN Spot Drill was designed with exclusive geometry angle on the engage point which gives awesome stability that conduces to excellent verticality precision on pilot pre-hole concentricity rate and improves life time of the drill and tap.

Indexable Engraving Tool

Y.T. indexable engraving tool offers you an accurate engraving solution on CNC machine. Patented double clamping 390 system and unique positive insert geometry design in 60° ensure you a precise and slim engraving line. Fully grinded insert fit on HSS "TU1" shank and Swiss screw, together with GA centralizer leads to a great concentricity and realize the possibility to change insert directly from the machine, without the needs to calibrate the tool length repeatedly. The Min. dia. on the insert starts from dia. 0.15 mm. With smallest eccentricity only 0.008mm, we make the great performance in tool life and speed possible.One single insert can be applied on different materials: Steel / Stainless steel / Non-ferrous metal and Plastic. Moreover, in the application such as product code, digital engraving, marking, trademark engraving and all CNC programing letters and images engraving.Y.T. indexable engraving tool widely used in the industries: Medical / defense / mold / automobile / gears / bearings, and boutique industries