Center Drill

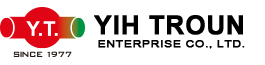

The indexable insert of YIH TROUN Center Drill is made from special carbide materials, it provides a sturdy and robust drill bit and offers the machining efficiency and tool life four times better than HSS center drills. With YIH TROUN Indexable Carbide Center Drill, users will get an overall 3 ~ 5 times cost saving from its supreme life time and the great time-reduction in frequently tool changing, re-centering and length calibrating.

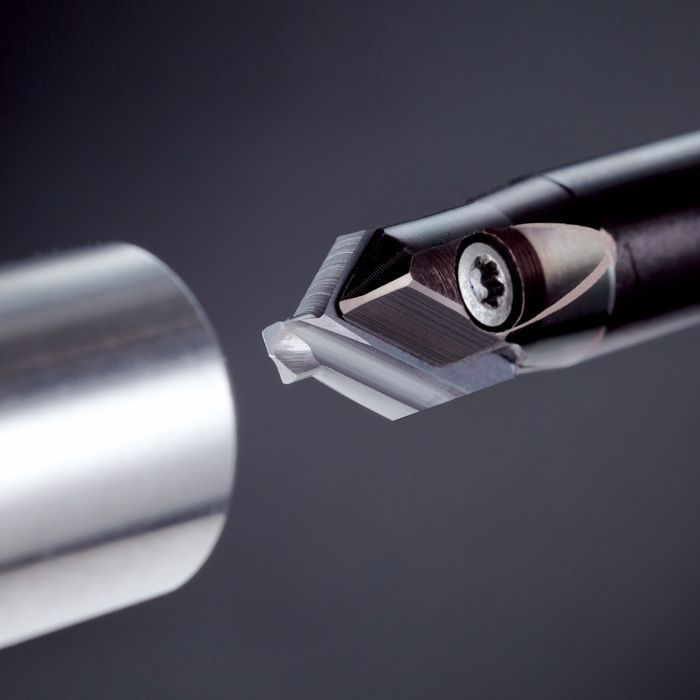

YIH TROUN indexable center drill features sandwich plug-and-clamp construction as well as tapered key special design. It stays eccentricity ± 0.008mm, approaches zero eccentric in stationary status. It is a dedicated indexable center drill for center facing machining by lathe, milling machine and drilling machine.

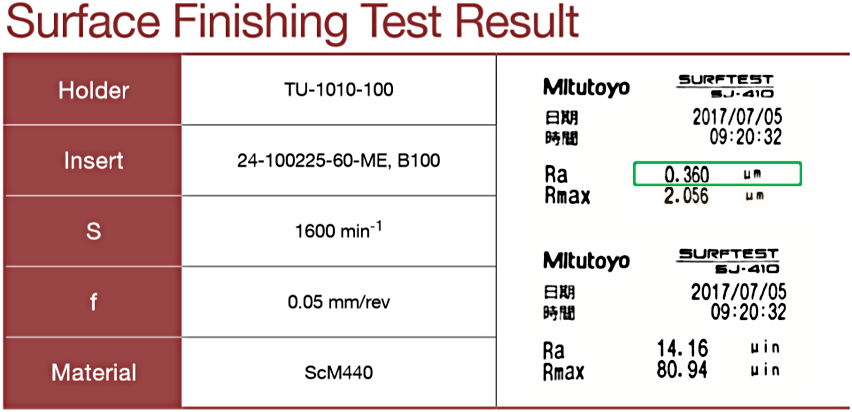

The two cutting edges are designed on balanced positions to decrease the high feed rotating runout and secure a surprising kinetic equilibrium. YIH TROUN indexable center drill was designed with exclusive geometry on the engage point which gives awesome stability that conduces to excellent verticality precision on pilot center drilling and reaches ≤ Ra0.36 cleanliness on machining surfaces.

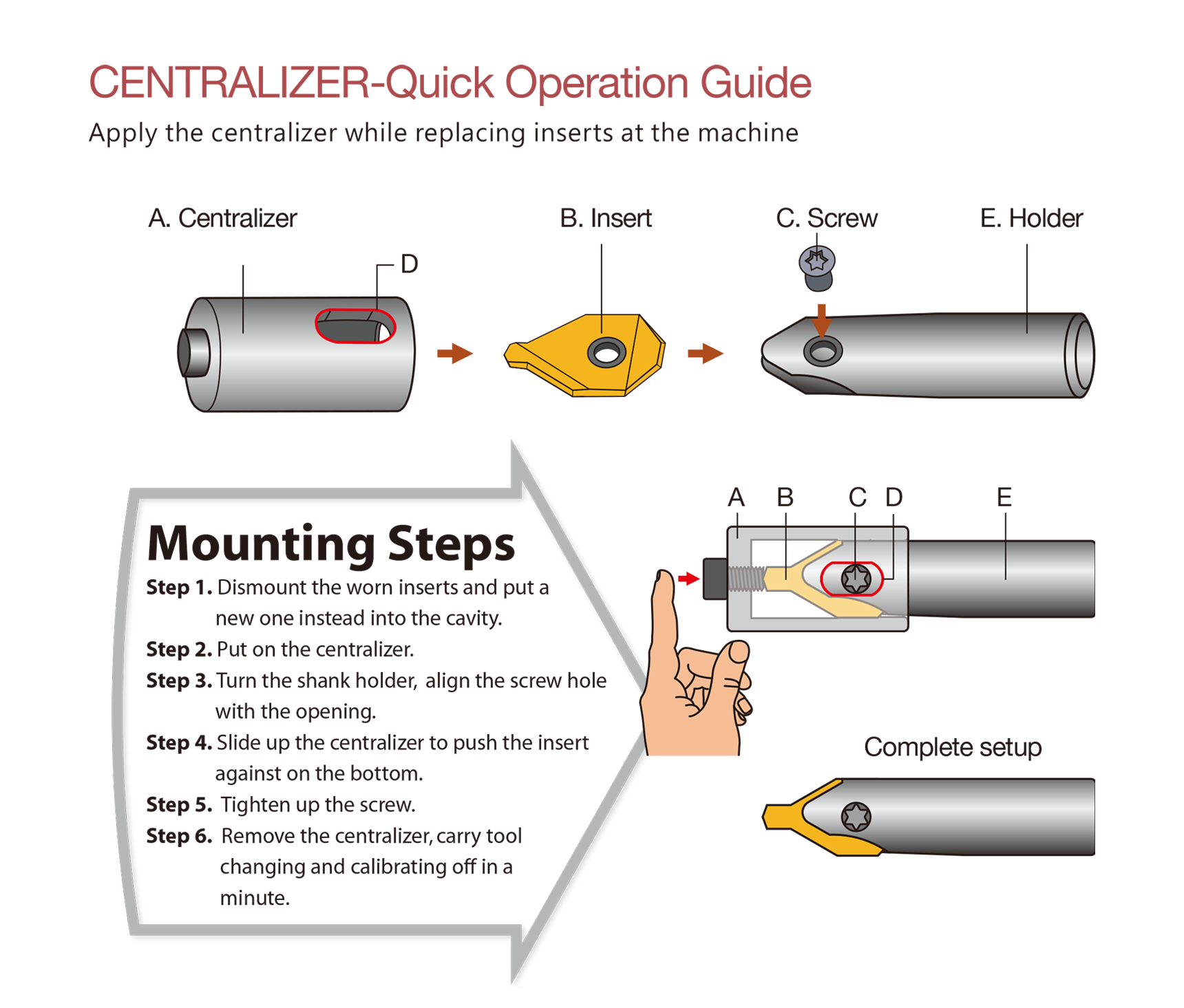

Whenever change tool, users must calibrate the tool length and eccentric point of the traditional solid center drill. YIH TROUN has developed a unique centralizer exclusively for the indexable center drill, it brings manufactures a fast plug-and-perform solution to help reducing the loss of production capacities caused by the suspension of work.

When using the dual-services centralizer, without removing the shank, even a junior machine operator can change the indexable insert in a minute and secure a surprising positioning accuracy at the same time.

Quick operation guide:

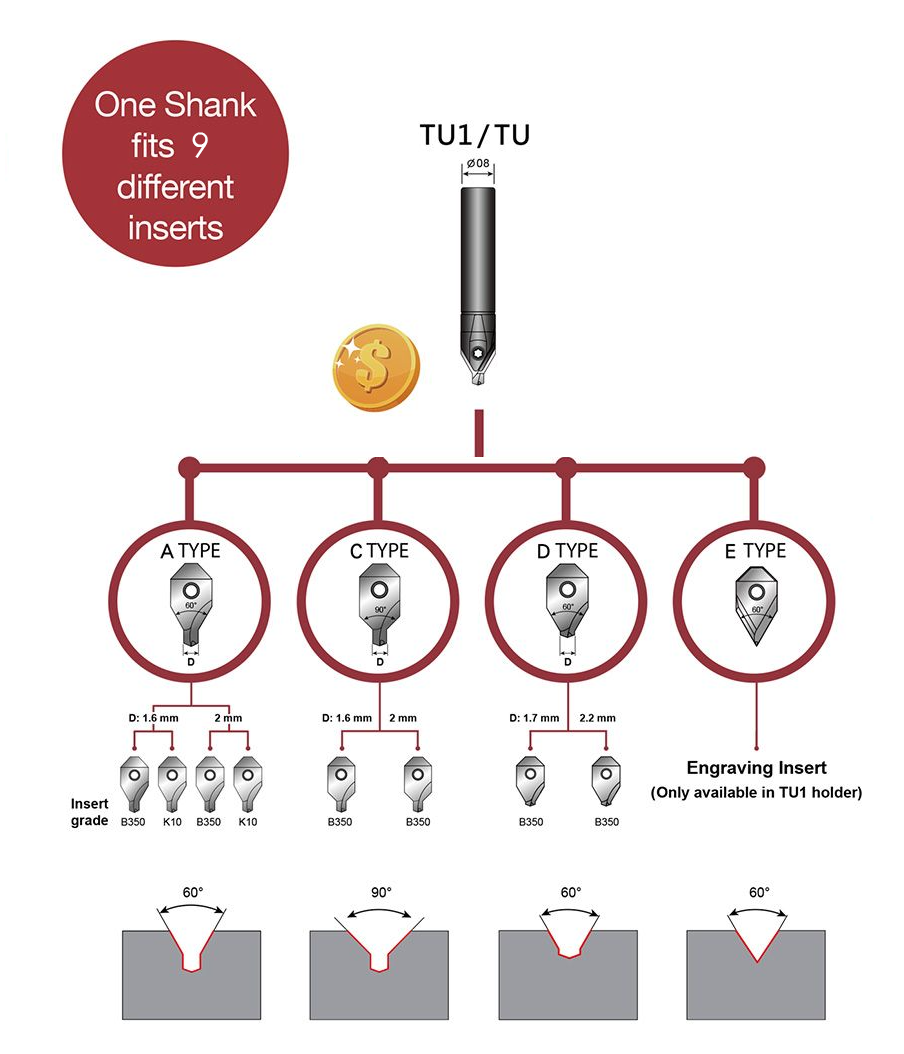

Great shareability

Each shank of the center drill is suitable for maximum 11 types of insert in different angles and sizes to different machining applications.

Applicable in different materials

To support machining a wide range of workpiece materials, YIH TROUN offers two grades of the indexable center drill in different grades of coating and cut edge:

1. E,K10 - Suitable for hole machining with aluminum, copper, alumino-nickel and non-ferrous materials.

2. ME,B350 - Widely suitable for hole machining with steel, harden alloy steel, stainless steel, cast iron and ductile iron materials.

Tool comparison

In the market, most of the indexable center drills were unsafely fastened on the surface side of shanks by only one tiny screw, no structural reinforcement clamping. Those kinds of drill bit keep high eccentricity over 0.02mm. Its low stabilities lead to greater cut resistance, can't put a good cleanliness on the chamfering surface and it precipitates the drill bit chipping soon.

There are also numbers of center drill made of high speed steel (HSS), the low hardness material is easy to wear during the machining process; we all know the wore drill bit gives short too life, not work well on center positioning.

It happens the drill bit drifts over the material surface while entry engagement, the pre-hole will be led to verticality deviation. YIH TROUN Indexable Center Drills have an edge on minimal eccentricity tolerances, it conduces to extremely accurate center positioning and be very helpful to extend tool life, decrease the attrition rate and lower cost on post-processing, specially to small size or deep hole machining.