Indexable Chamfer Series

In order to remove burrs generated after machining or let work piece look more valuable, machining is usually implemented with chamfering cutter.

Chamfering cutter is normally classified in several categories:

A. Frequently Used Angles:

60° / 90°/ 100°/ 120°

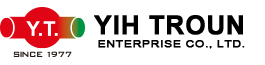

B. Frequently Used Machine

Hand tool / General drilling machine / CNC milling machine

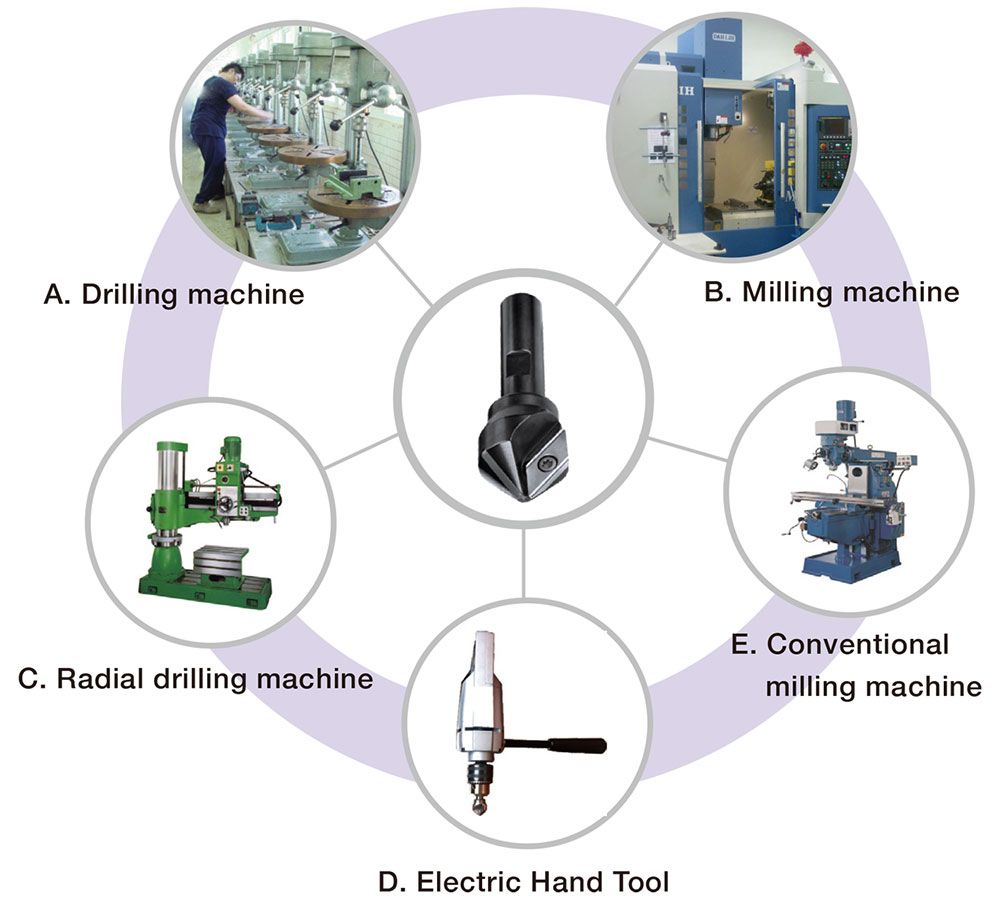

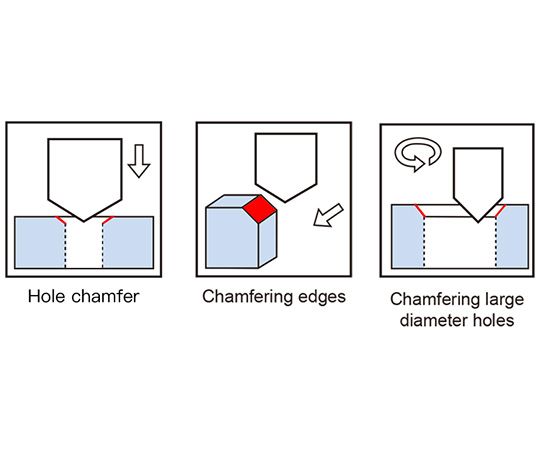

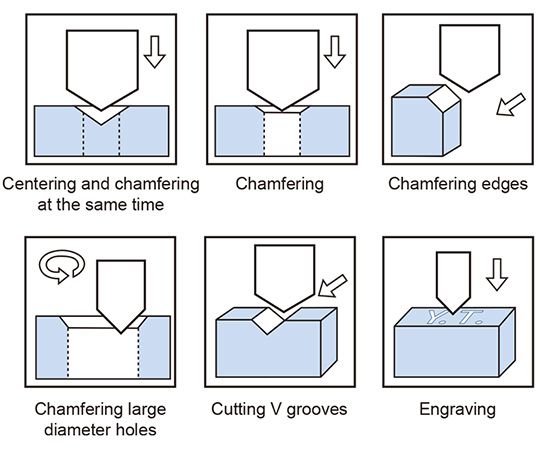

C. Chamfer Types

C Chamfer / R Chamfer

YIH TROUN's all indexable chamfering cutter series include various machines in use: general drilling machine, CNC milling machine, manual tool and every general angle. Their usages are classified as below:

1.CI Series of Chamfer King for Drilling Machine

Mainly used on drilling machine but also available for CNC spindle for vertical or horizontal movement. It is not recommended to be used with CNC program. Holder has carbide stripe design to enhance arbor strength. It is only necessary to replace carbide insert for each time without replacing the cutter body. There is no problem to use slower RPM in drilling machine. Cutting-edge length of carbide chamfering insert is up to 40mm long, it covers wide range of chamfering depth.

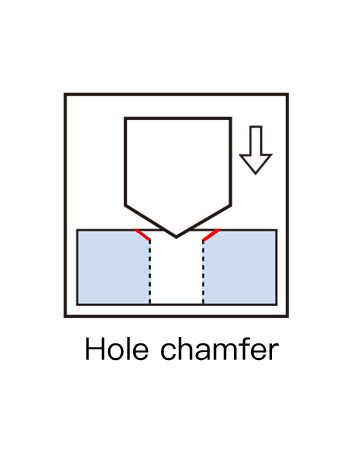

2. C Series of Chamfering Cutter for CNC

It can be used on spindle for vertical or horizontal linear movement or movement along various paths according to CNC program. Single cutting edges length of carbide chamfering insert is up to 40mm, it covers wide range of chamfering depth. Max. 3 cutting flutes are allowed for holes of small diameter with chamfers of 45 degrees.

3. 13-Series of Spot Drill and Chamfering Cutter

Series of multi-functional tool can be used on drilling machine and CNC milling machine. They can be used not only for chamfering but also used for engraving and as spotting drill.

4. 15-Series of Indexable Corner Rounding Cutter

Corner rounding cutter used on CNC milling machine. Carbide inserts from radius R1-R10 all have standard inventory. Insert has two cutting flutes with quicker efficiency.

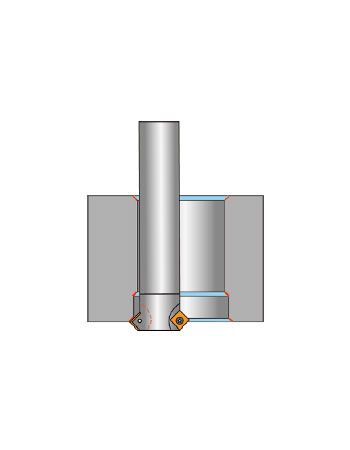

5. MC Series of Upper / Lower Chamfering Cutter for CNC

It can be used for both upper and back chamfer at same holder. Carbide insert has four cutting edges applicable. Minimal hole diameter with chamfer starts from 11mm.

-

Chamfer Milling Cutter

For CNC machining chamfer cutter, we offer 2 different cutters in indexable design: A. MC / HMC Cutter B. C Cutter

-

Corner Rounding Cutter

Indexable corner rounding cutter of YIH TROUN is able to be equipped with max. 10 different inserts regarding chamfer selection. Offset of insert is only ± 0.008 mm and thus achieve excellent chamfer finish. Carbide insert angles are classified into small radius R1 ~ R5 and big radius R6 ~ R10. There are PVD coating with golden color and rose gold color available which can be installed on holder with small diameter Ø 16 and Ø 25. Effective no. of teeth is 2 teeth which can double machining efficiency and it also raises chamfer machining efficiency.