Indexable Slitting / Slotting / Cut-Off Series

Voyager of groove machining

YIH TROUN with its entire series of slitting, slotting and cut-off is the manufacturer of grooving tools with the most complete specification selection worldwide. For variable machining scenarios, YIH TROUN provides diversified choices, respectively for outer diameter, thickness, patented clamping system, types of insert chip evacuation, insert grade, connection system, arbor clamping system and special machining application. Different from design of other brands, YIH TROUN is committed to promoting more choices for grooving industry and to create excellent as well as consistent machining results. With guarantee from patents, continuous usage by over 4000 customers, witness around 61 countries, YIH TROUN groove machining series are the best choice in the machining industry.

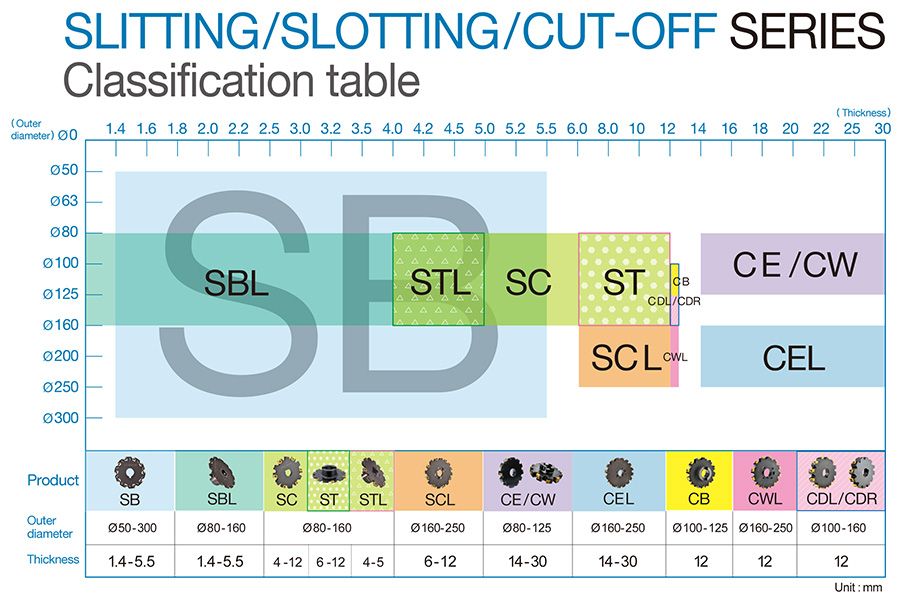

Classification Table

The classification table classifies diverse products according to outer diameter and thickness.

Outer diameter: D50 ~ 300, creating the most complete outer diameter options, which is the best in this industry. The whole series of tool provide various arbor clamping structure design to be applied on multiple machines:

Thickness: 1.4 ~ 30mm, creating excellent flatness, which is the best in this industry.

1. Connection Method: Flat type, T-shaped indexable type, T-shaped one-piece type

2. Arbor Clamping System: Side milling arbor, face milling arbor, ER / side lock arbor

3. Special Machining Application: Back milling cutter, Special straddle side milling cutter

-

Saw Blade

Saftest Saw Blade

YIH TROUN's patented clamping design structure ensures the stability and strength of carbide insert locking. It possesses decent clamping function and tool life even under high cutting speed. Better clamping system brings higher production efficiency. Maximal speed of 17200 RPM is certified by Sweden.

-

Adaptor Holder Series

In order to provide customers more sharable choices by procurement of T-slot tool, modular design can not only save inventory cost of cutting tools, but also enhance the stability of cutter by center square positioning design, connection in cutter and holder, as wells as locking with 4 screws. Through the modular adaptor holder design, end user can use their current face milling arbor. Such kind of combined cutter has non-protruded flat bottom and will not cause the issue of interference with bottom.

-

Large Adaptor Holder Series

In order to provide customers more sharable options by purchasing of side milling cutter, modular design can not only save inventory cost of cutting tools, but the non-protruded flat cutter bottom will also not cause the issue of interference with bottom. Besides, we enhance the stability of cutting tools through central locking system between disc milling cutter and holder as well as locking with 4 screws. Through the modular design, users can fit various cutters as they wish. Besides, once situation such as cutter collision occurs during machining, it can avoid damaging the whole set of cutters. Only replacement of damaged cutter is necessary. Large sized adaptor holder cutter include inner holes in imperial units and metric units.

-

Side Milling Cutter

Compared to traditional high-speed steel cutter and brazed side milling cutter, YIH TROUN's indexable side milling cutter can bring more economical and higher efficient solution for slotting and cut-off machining. Compared to brazed side milling cutter, indexable cutter can replace carbide insert more conveniently to save replacement time. Geometry of carbide insert can achieve better machining efficiency and life. In the meantime, insert can use 4 cutting edges simultaneously and thus save tool cost effectively.

-

Disc Milling Cutter

Are you willing to remove metal material rapidly and save machining time? Indexable disc milling cutter is absolutely the first choice for wide slot machining! Integral pre-harden steel cutter is equipped with three carbide inserts CNGX 1005 / 1305 / 1605 to increase your efficiency in heavy machining or roughing. Fully grinded G-grade insert provides higher machining precision and insert life as well as better chip evacuation; special chip evacuation geometry on insert is able to effectively reduce machining resistance during rapid material removal.

-

Back and Straddle Cutter

YIH TROUN disc milling cutter is exclusively designed for the requirements of heavy machining, highly efficient machining, bottom machining and simultaneous machining dimensions on both sides. Especially in connection with automobile parts which needs to remove material on both sides simultaneously, or machining on bottom of large work piece, disc milling cutter is absolutely the best choice. Besides, greater thickness of disc milling cutter can also enhance the stability of machining, however, it also needs larger machine and horsepower. In order to achieve maximal benefit for production line, YIH TROUN's R&D team has also development depart targeted at customization requirement to accomplish optimized design according to each machine, production capacity and production cost.